A remark made by President Obama during his address to a Joint Session of Congress in 2009 referred to his goal of having every American receive at least one year of postsecondary education, thus attaining the highest proportion of college graduates in the world by 2020. That goal begins to show its first signs of life this month.

The Trade Adjustment Assistance Community College and Career Training Initiative will provide at least $2.5 million per state for community college training programs that are mainly focused on advanced manufacturing. The idea is that the recipient of this grant will use the funds to create affordable training programs that meet industry needs, invest in staff and educational resources, and provide access to free, digital learning materials.

In other words, it was created to expand the capability to accommodate dislocated workers and others who are waiting for training. The Northeast Wisconsin Technical College Consortium, a group of all of the 16 Wisconsin technical colleges including MATC, has been awarded $14.9 million, giving MATC close to $1.4 million.

So what does this mean for Wisconsin, and more importantly MATC? Specifically, how will MATC use this money to improve manufacturing and employment chances?

Duane Schultz, Associate Dean of the School of Technology and Applied Sciences at MATC, spoke about how the grant will improve manufacturing education at MATC, “A part of this grant is really focused on dislocated workers and workers who have been impacted by their jobs going overseas. Right now, there are more than 100 people waiting for welding slots at MATC alone, so they could be designated as eligible for Trade Assistance Adjustment resources. Secondly, we are looking to develop a new curriculum for metal fabrication and at the same time expand the number of students we can get into the program. We are moving forward to put in place a metal fabrication program at the Mequon Campus and we are going to do some curriculum development in each [department].”

Another part of this initiative will be to work closely with other schools that already have such a program in place to edit and finalize the actual curriculum itself. Schultz spoke of one of the main conflicts occurring on the machining side, “Right now what tends to happen is a student gets the opportunity to get a job and They’re not interested in getting their final graduation at MATC. They’re interested in getting a job because they need one and that’s understandable.

“However, the way our data systems work it makes it appear as though all that we did was have a failed student; so part of the fix is to use the sources within the grant so that we are, number one, not penalized as an institution; and number two, acknowledging and recognizing the work that the student is doing. We want to give them the certificate credential on their way out the door.”

As President Obama said in his address in 2009, “In a global economy where the most valuable skill you can sell is your knowledge, a good education is no longer just a pathway to opportunity – it is a pre-requisite.”

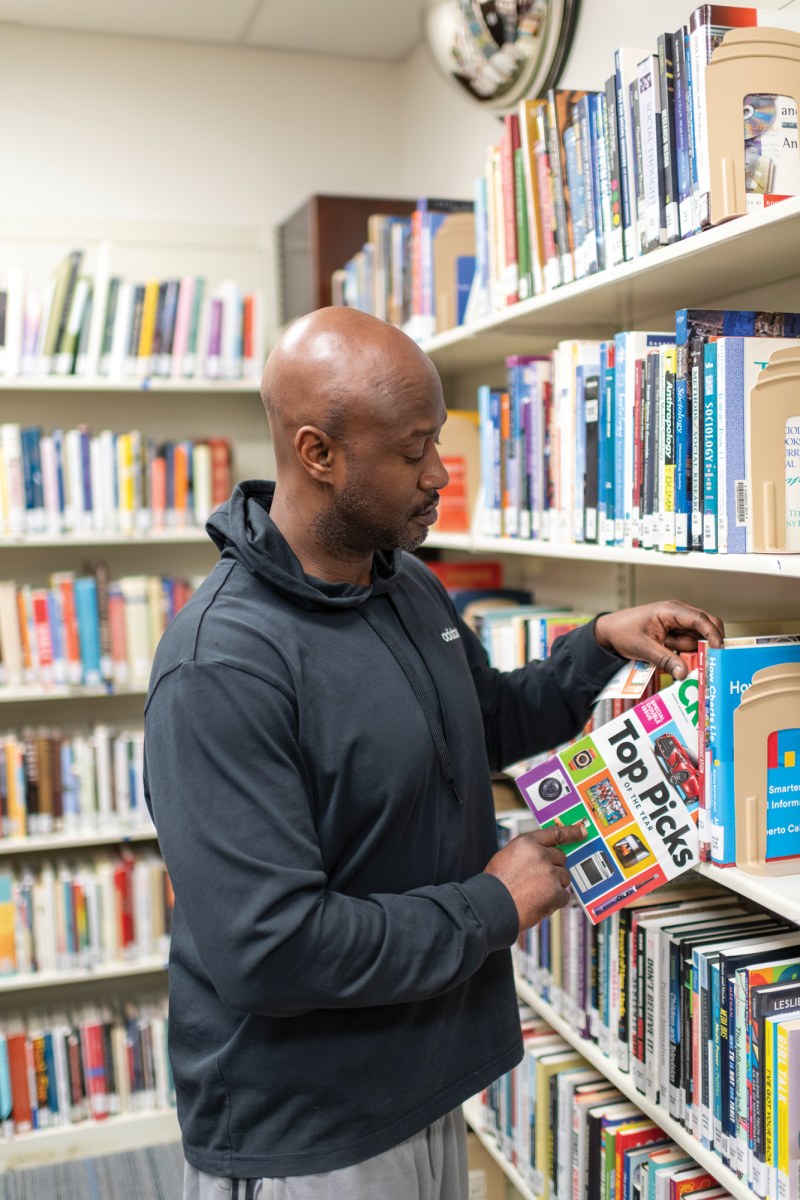

So, what happens when there’s a waiting list on that education? Regionally, manufacturers have weathered the storm of the economic downturn because they supply the parts that are always in demand. Parts always need to be made, production always needs to continue, but the one thing that’s being observed is a bottleneck in the production of the worker.

With so many in line for an education just to get into a manufacturing or welding position the real demand is for space and the resources to create the worker.

Hopefully, this initiative is a step in the right direction. Hopefully, it’s only one step of many.

Quote of the Day

- Spring is nature's way of saying, 'Let's party'! – Robin Williams