Open house shows off six new Swiss CNC machines

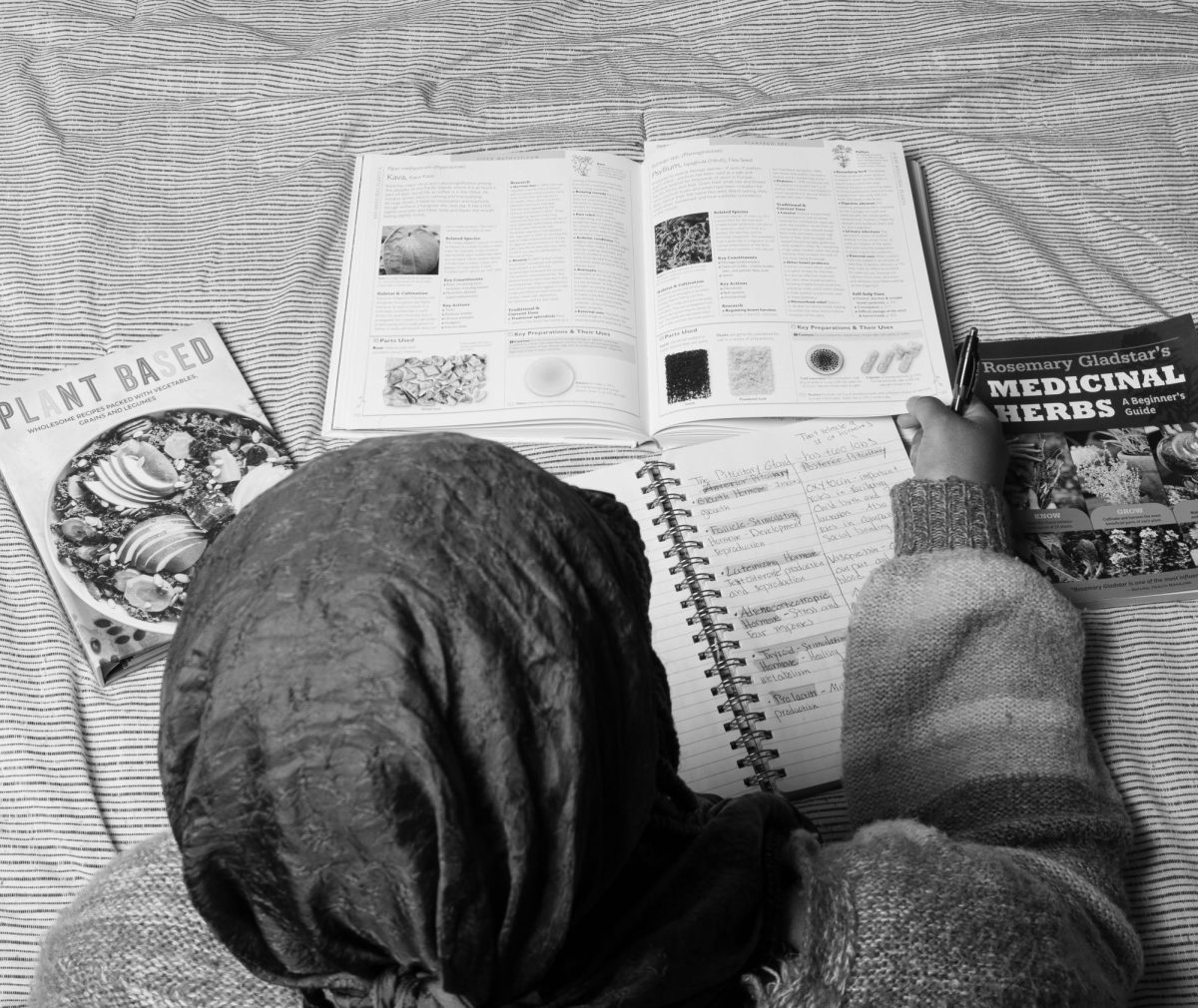

Photo by Sefton Ipock

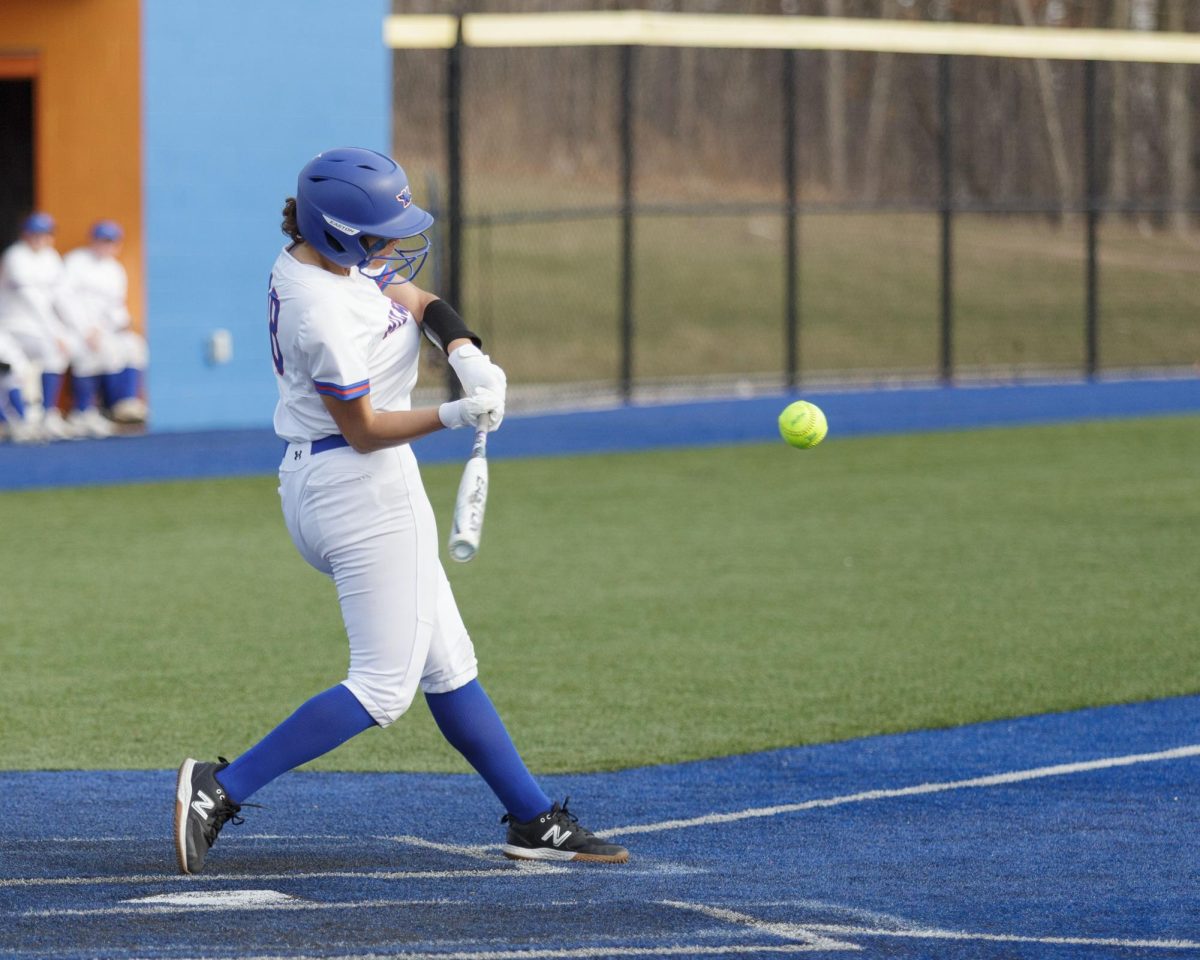

Corey B. Johnson, (second from left) president of Morris Midwest, Dr. Vicki Martin (third from the left) MATC president, and Dorothy Walker, interim dean of MATC’s School of Technical and Applied Sciences, cut the ribbon on the college’s new CNC Swiss lab on Oct. 17 at the Downtown Milwaukee Campus.

MATC recently added new state-of-the-art equipment to enhance training for its CNC (computer numerical control) Swiss machine tool operations classes. Six new Tsugami precision machine tools were purchased and installed at MATC’s Downtown Milwaukee Campus in recent months.

On Oct. 17 MATC hosted an open house to introduce area students, educators, manufacturers and community leaders to its new CNC Swiss lab.

According to Dorothy Walker, interim dean of MATC’s School of Technical and Applied Sciences, the college expanded its capacity for Swiss CNC training this fall in response to a growing need from local employers for CNC Swiss machine programmers, setup technicians and operators. MATC is the only technical college in Wisconsin that offers a full technical diploma in CNC Swiss machining.

“Manufacturers used to rely on manually operated screw machines,” said Walker. “With the advent and adoption of CNC Swiss machines, manufacturers can rapidly produce complicated parts with high accuracy and repeatability, increasing their production capabilities and ability to compete for business locally and globally. We have been offering training on CNC Swiss machines for some time, but we wanted to be able to serve more students and upgrade equipment to ensure that our students would be learning on the newest technology.”

The two-semester program called “Machine Tool Operations: CNC Swiss Turning Setup and Operation” extends beyond machining basics, providing hands-on training on Tsugami Swiss-type CNC lathes, highly accurate machines commonly employed in the production of small, precision parts ranging from household hardware and plumbing supplies to medical, dental, aerospace and automotive components, among others.

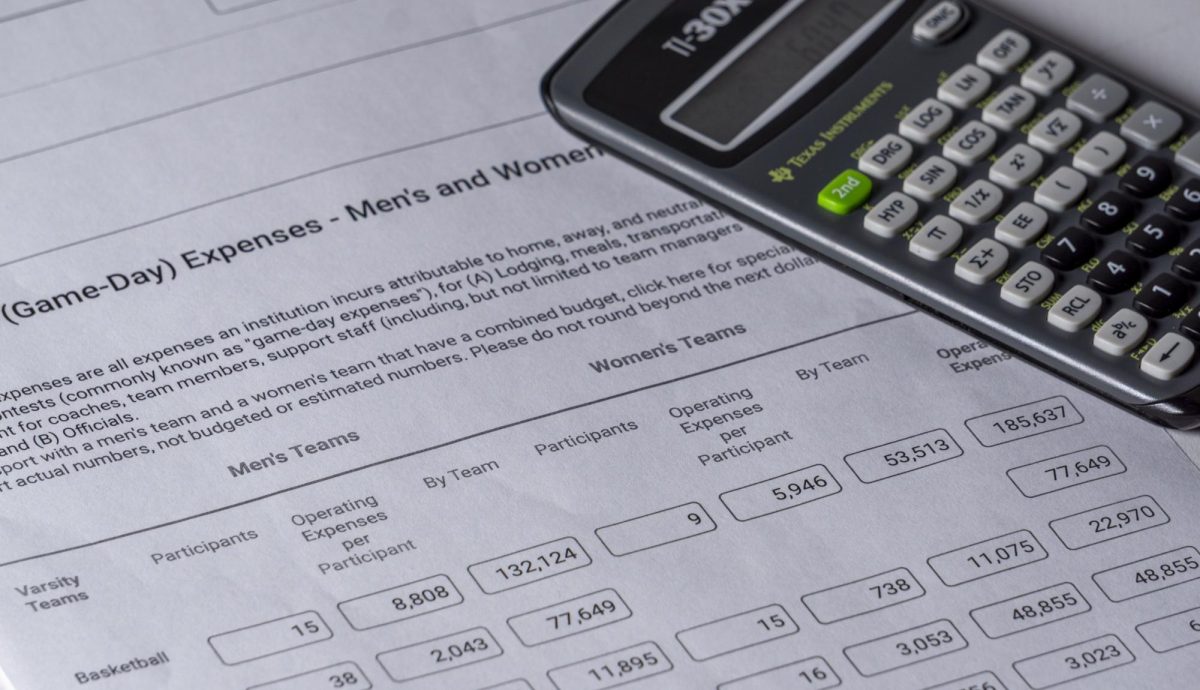

To enhance its already robust program that provides a technical diploma and readily employable skills, MATC purchased the new Tsugami precision machine tools from Morris Midwest, a full-service regional machine tool distributor with offices in Waukesha; Roselle, Illinois, and Maple Grove, Minnesota. Machine models include the Tsugami S205 20 mm Swiss-type CNC lathe with five cutting axes; the SS207-5AX 20 mm Swiss type CNC lathe with seven cutting axes including a B-axis for complex machining and contouring, and the BW209Z 20 mm Swiss-type CNC lathe with nine cutting axes. Morris Midwest, a division of Morris Group Inc., installed the machinery at MATC’s Downtown Milwaukee Campus.

According to Chris Chomicki, MATC machine tool instructor, one of the reasons the college considered the Tsugami brand is because of the dual gang tooling configuration of the machines, a helpful feature when conducting two classes in conjunction with one another. A second attractive feature was the flexibility to convert the machines from typical Swiss-type bar-fed operation to conventional work holding mode with an optional chucker kit. Morris Midwest’s reputation as a trusted supplier was an added factor in the school’s decision to purchase the globally recognized Tsugami brand.

Instruction in CNC Swiss turning at MATC takes students through the steps of setting up and programming a machine. Students begin the learning process by editing virtual programs on tablets and progress to programming the machines for live cutting. Students who successfully complete the two-semester program obtain a technical diploma that can be applied to further study at MATC.

“We’re thrilled that MATC chose to install Tsugami CNC precision machine tools at the school,” said Corey B. Johnson, president, Morris Midwest. “Working with area manufacturers as we do, we’re aware of the need for skilled CNC programmers and machinists and are honored to support workforce development in partnership with MATC. Specialized skills in CNC Swiss turning are a valuable asset for anyone seeking employment in metal cutting.”